Building Structure Design: How to Plan and Detail Structural Engineering for Buildings

Every building starts long before the first brick is laid. Beneath the walls, floors, and finishes lies a framework of thought, analysis, and precision — that’s building structural design. It’s the unseen blueprint that ensures buildings stay upright, resist wind and earthquakes, and serve their purpose safely for decades.

Building structure design is the process of planning and engineering the structural elements of a building — from the foundation to the roof — so that it performs under all expected conditions. It’s a blend of creativity, physics, materials science, and code compliance.

At Exactus Engineering, we treat structure not just as something that holds a building up — but as something that shapes how it performs, how efficiently it’s built, and how it lasts.

What Is Structure Design for Buildings?

In construction, structural design is all about turning ideas into reality — safely. It's the phase where engineers define how a building will support loads, resist movement, and maintain integrity over time.

Key objectives of structural design:

Support – The structure must carry its own weight and any added loads.

Stability – It should resist collapse, sway, or tilt under external forces.

Safety – Occupants must be protected under all usage scenarios, including extreme events.

Durability – The design should perform reliably for the building’s intended lifespan.

Architect vs Structural Engineer:

While architects define the building’s aesthetics and functionality, structural engineers make those forms possible — by analyzing loads, choosing systems, and detailing how everything connects. One designs for vision; the other ensures it stands.

Key Principles of Structural Engineering in Building Design

Every structure stands on a few key engineering principles. These guide how we analyze forces, choose materials, and design systems that are both safe and efficient.

Load-Bearing Principles

Buildings are constantly under loads, including:

Dead loads (permanent weight: floors, walls, roofs)

Live loads (occupants, furniture, equipment)

Environmental loads (wind, snow, seismic)

A structural design must calculate how these forces travel through the building and into the ground — and size every beam, slab, and column accordingly.

Stability and Equilibrium

A stable structure resists tipping, sliding, or collapsing. We design systems to remain in equilibrium even during high winds or earthquakes — distributing forces logically across the structure.

Material Behavior

Every material behaves differently:

Concrete excels in compression but needs reinforcement in tension.

Steel handles both tension and compression but expands with heat.

Wood is lightweight and renewable but susceptible to moisture.

Understanding these behaviors lets us combine materials wisely and design for long-term performance.

Serviceability

It’s not just about not falling down — it’s about performing well. Serviceability means the building doesn’t deflect excessively, vibrate, or crack under normal use. These “comfort factors” are often what owners and users notice first.

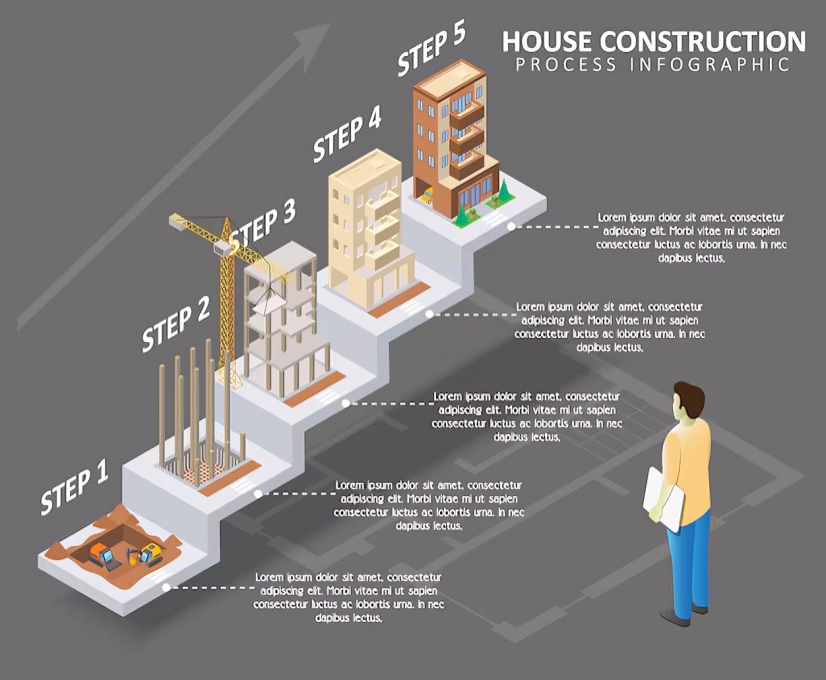

Step-by-Step Structural Design Process

Designing a structure isn’t a single step — it’s a sequence of critical decisions and calculations, each building on the last. Here's how structural design usually unfolds in a professional engineering workflow:

1. Client & Architect Consultation

We begin by understanding the building's purpose, site conditions, aesthetic goals, and functional needs. Is it a residential villa, a data center, or a school in a seismic zone? Every use case affects how the structure will be designed.

2. Preliminary Design

This is where big-picture decisions happen. We define column grids, slab systems, foundation concepts, and possible structural materials. It’s about matching vision with engineering feasibility.

3. Load Calculations

Using building codes and real-world assumptions, we calculate dead loads, live loads, environmental loads (wind, seismic, snow), and special conditions like equipment weight or soil pressure.

4. Structural Analysis

We run simulations (via software or manual checks) to see how the proposed structure will respond to loads. This includes deflection, force distribution, and stress checks across every element.

5. Structural Detailing

Once the structure is proven stable, we create the detailed drawings: beams, rebar, columns, slabs, connections, and joints. These documents guide the contractors on exactly how to build it.

6. Peer Review & Quality Assurance

Before plans are sealed, another licensed engineer reviews the design to check for errors, code compliance, and constructability issues. This step is critical for reducing risks during construction.

7. Permit Submittals

We finalize drawings, calculations, and engineering reports for submission to the local authority or permitting office. These must meet local codes and engineering best practices to gain approval.

Structural Design vs Structural Detailing

These two often get lumped together, but they’re very different — and both are essential.

Structural Design is the conceptual and analytical phase. It’s where we figure out what kind of structure is needed, how big elements must be, and how they perform under stress.

Structural Detailing is where we translate that design into exact construction documents — including material specs, rebar placement, weld sizes, bolt patterns, etc.

Think of design as planning the trip. Detailing is writing turn-by-turn directions.

Without strong design, the structure may fail. Without good detailing, the builder may not know how to build it correctly — or safely.

Types of Building Structures and Systems

Depending on the building’s size, location, and purpose, we choose different structural systems. Here are some common ones:

Load-Bearing Structures

Used in small-scale or low-rise buildings, these rely on walls to carry loads. They’re cost-effective but limit flexibility in layout and expansion.

Framed Structures

These use steel, concrete, or wood frames (columns + beams) to carry loads. Ideal for larger buildings where open space and multi-storey flexibility are needed.

Pre-Engineered Buildings (PEB)

Popular in industrial and warehouse projects, these are manufactured off-site and assembled quickly. Fast and efficient, but limited to standardized configurations.

Composite Systems

Combining steel and concrete, these offer enhanced performance. For example, steel frames with concrete slabs provide strength and cost savings.

Shear Wall and Core Systems

Used in tall or seismic-prone buildings, these systems resist lateral forces from wind and earthquakes. They’re often integrated into stairwells and elevator cores.

Materials Used in Structural Design

The materials we choose shape everything — from the cost of construction to the longevity and performance of a building. Each project demands a tailored approach based on structural needs, budget, and architectural intent.

Concrete

Cast-in-place concrete is poured on-site — ideal for custom shapes, slabs, and foundations.

Precast concrete is manufactured off-site and assembled on-site — great for speed and quality control.

Concrete is durable and excellent in compression, but it needs steel reinforcement to handle tension — that’s where rebar comes in.

Steel

Steel is the go-to for high-strength, high-rise, and long-span applications. It's flexible under load, resists cracking, and allows for fast erection. Common forms include:

I-beams and H-columns

Moment-resisting frames

Steel decking for floors and roofs

Timber

Engineered wood products like glulam and CLT (cross-laminated timber) are gaining popularity for sustainability and aesthetics. They work well for low- to mid-rise buildings and are ideal in regions focused on carbon reduction.

Masonry

Used in both load-bearing and infill walls, structural masonry can include:

Concrete blocks

Brickwork It offers fire resistance and thermal mass but needs careful detailing to avoid cracking.

Hybrid Materials

More and more designs now combine materials for efficiency. Steel and concrete composites, timber-steel combos, or masonry frames with reinforced cores offer performance without overdesign.

At Exactus, we always match the material to the real-world performance needed — not just what looks good on paper.

Building Codes and Standards in Structural Engineering

Every structure must meet local and national codes — not just for safety, but also for legal compliance and permit approval.

Common Codes and Standards:

IBC (International Building Code) – baseline for most US projects

ASCE 7 – guidelines for calculating loads (wind, snow, seismic)

ACI – concrete design standards

AISC – steel design and detailing standards

CSA / NBCC – Canadian codes

Eurocode – for projects in Europe or international standards

Local building departments often have their own amendments or versions, and Exactus ensures every design is tailored to those jurisdictional needs.

Why Code Compliance Matters

Safety – Prevents structural failure under real-world conditions

Permitting – Required for legal construction approval

Liability Protection – Ensures professional responsibility and legal coverage

We take code compliance seriously — not just because it's required, but because it protects people and projects.

Structural Analysis Tools and Software

Modern engineering demands more than pencil sketches and gut instincts. We rely on powerful software tools to model, analyze, and optimize every structural system.

Popular Software We Use:

ETABS – for analyzing multi-storey buildings

SAP2000 – for general structural analysis

STAAD Pro – for international or complex structures

Tekla Structures – for 3D detailing and coordination

Revit – for Building Information Modeling (BIM)

These tools help us test how a structure will behave before it’s built — under every type of load, in every condition.

We don’t guess — we simulate, iterate, and optimize.

Detailing Drawings: What They Include

A great structural design means nothing if it can’t be built properly — that’s where detailing comes in. Structural detailing bridges the gap between concept and construction, showing how every beam, rebar, and bolt comes together on site.

What You’ll Find in Structural Drawings:

Plans and Elevations: Top-down views and vertical profiles showing layouts, levels, and gridlines.

Sections: Cut-through views of walls, floors, or structural cores for deeper understanding.

Schedules: Lists of structural elements — beams, columns, rebar, bolts — with sizes and quantities.

Reinforcement Details: Specifics for concrete members — bar sizes, spacing, cover, and lap lengths.

Steel Connection Details: Welds, bolts, gusset plates, base plates, and how different elements connect.

All of these need to align with architectural and MEP drawings — otherwise, you’re heading for costly conflicts and field revisions.

Common Mistakes in Structural Design — and How to Avoid Them

Even experienced teams can fall into traps. Structural design isn’t just about calculations — it’s about coordination, constructability, and foresight.

Common Pitfalls:

Underestimating Loads or Deflections: Leads to cracking, sagging, or even failure. We always account for worst-case scenarios.

Overdesign: Too much steel or concrete makes the project unnecessarily expensive. The goal is optimal, not excessive.

Lack of Coordination: Misalignment between structural and architectural/MEP drawings can cause onsite clashes. Our team works cross-discipline from day one.

Ignoring Site Constraints: Tight urban lots, sloped terrain, or poor soil can all derail a design that looked perfect on paper.

At Exactus, our QA/QC process includes peer reviews, software checks, and constructability assessments — because fixing it on paper is cheaper than in the field.

Structural Design for Different Building Types

Not all buildings are created equal — and neither are their structural needs. Each type brings unique challenges, loads, and expectations.

Residential Homes

Simpler load paths

Often wood or light steel framing

Focus on cost, insulation, and speed of construction

Commercial Buildings

Open floor plans mean longer spans

Requires higher live load capacity (for people, equipment)

Common systems: steel frames, composite decks

Multi-Storey Structures

Complex load transfer between floors

Elevator cores, stairwells, and lateral systems become critical

Must account for wind and seismic forces

Industrial Facilities

Heavy equipment loads, cranes, and tall open interiors

Often need large spans with minimal columns (steel trusses or pre-engineered buildings)

Designed for function first

Renovations and Retrofits

Existing structure may be undocumented or degraded

Requires invasive investigation and adaptive reuse

Seismic retrofitting often needed for older buildings

At Exactus, we tailor structural solutions based on what the building is, what it’s used for, and what the site allows — not just generic templates.

Why Choose Exactus Engineering for Structural Building Design

At Exactus Engineering, structural design isn’t just a service — it’s a collaboration. We approach every project with the understanding that no two buildings are the same. That’s why our structural solutions are custom-built, not off-the-shelf.

What Sets Us Apart:

Holistic Design + Detailing

We don’t just design the structure — we detail how it’ll be built, ensuring clarity, accuracy, and constructibility from day one.Modern Tools, Human Insight

We use advanced software like ETABS, Tekla, Revit, and SAP2000 to model and simulate behavior, but we never rely solely on software. Our seasoned engineers bring real-world experience to every calculation.Collaborative Mindset

Whether it’s working alongside architects during concept design or syncing closely with contractors during construction, we believe in communication over silos. That’s how smart designs actually get built the right way.Cost-Conscious and Code-Compliant

We balance performance, safety, and budget — all while ensuring every plan meets local building codes and passes permit reviews smoothly.

From a single-story residence to a complex high-rise, we bring the right blend of technical rigor, creativity, and practicality.

Build with Confidence, Build with Exactus

Structural design isn’t just about beams and columns — it’s about creating buildings that last, perform, and support everything inside them. A well-engineered structure:

Ensures occupant safety

Controls costs during construction

Adapts to architectural goals

Reduces long-term maintenance and risk

If you're planning your next building project, don’t leave structure to chance. Let Exactus Engineering guide you from concept to construction — with expertise you can count on.