What Is a Helical Pile Foundation and Why It’s Reshaping Modern Construction

We’ve all been there. Standing on a project site, you get the soil report back, and there’s that sinking feeling. Unstable clay, tight property lines, a client on a non-negotiable timeline. The old playbook—digging a massive hole, pouring tons of concrete—was going to be a noisy, expensive, and messy disaster. We’ve stood on that ground, trying to figure out a better way forward.

The pressure is always on to build smarter, faster, and with less of a footprint. And let's be honest, in dense urban areas or on tricky land, the traditional methods often create more problems than they solve. They're just too slow and disruptive. This is where helical piles became a standard part of our toolkit. At first glance, screwing a foundation into the ground seems too simple, but it’s a seriously clever engineering fix. It lets us handle bad soil, work in tight spots, and support everything from a custom home to a commercial building without turning the site into a mud pit.

This isn't some new, untested gimmick. It's a blend of really smart, modern installation tech with engineering principles that have been proven for over a century. We’re using them to solve problems for our clients every day, cutting down on delays and the environmental headaches that come with heavy excavation.

The Basics: What Makes Helical Piles Unique

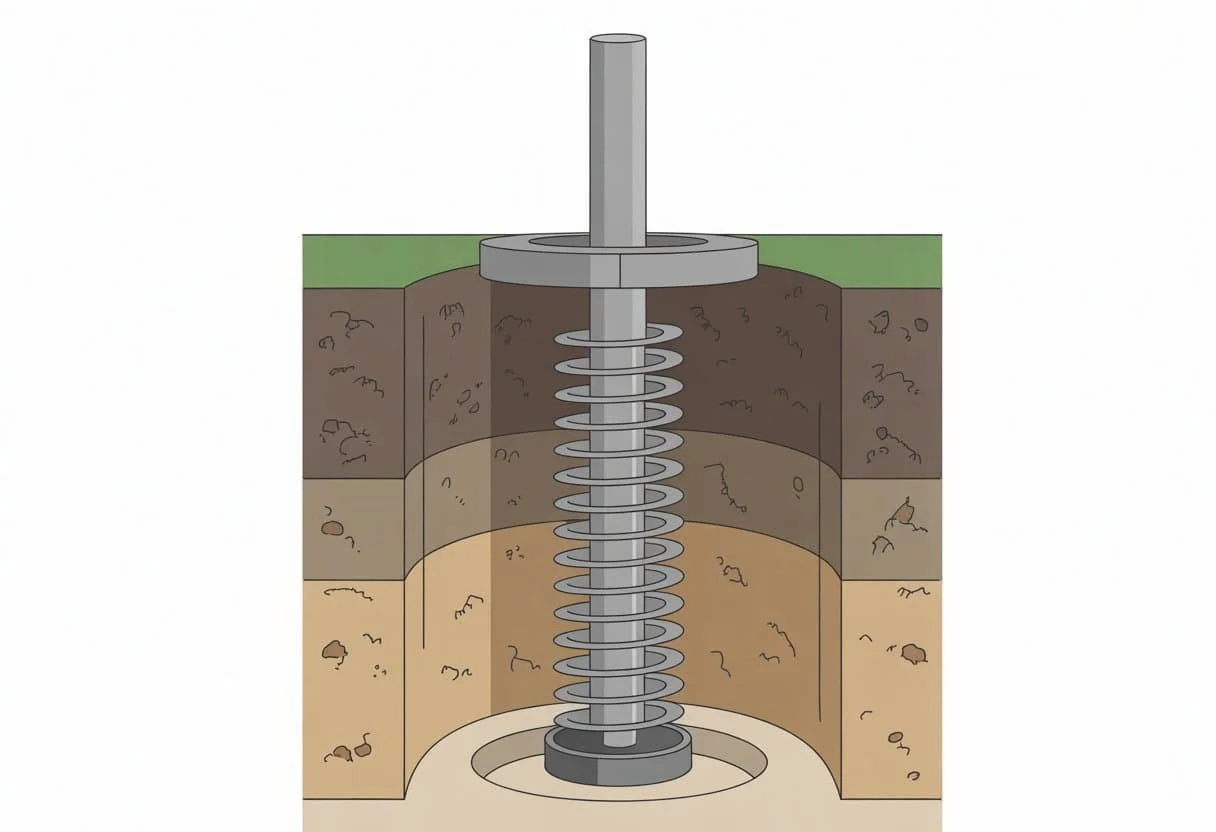

So what are these things, really? In the simplest terms, we think of them as giant steel screws. They have a central shaft, and then these spiral plates—the helices—that are welded on. Those plates are the key; they're what allows the pile to corkscrew its way down into the earth.

This is what truly sets them apart from other systems. We’re not hammering and vibrating the daylights out of the ground like you do with driven piles. Instead, our equipment just smoothly twists them into the soil. It’s quieter, way less disruptive, and we’re not displacing a bunch of dirt that then has to be hauled away. What we really appreciate on-site is how clean the whole process is.

Screw piles offer several advantages over poured concrete footings:

- Immediate load capacity - no curing time required

- Year-round installation - weather independent

- Precise depth control - stop at exact bearing capacity

- Removable and reusable - environmentally friendly option

The beauty of the design is that it can anchor deep into multiple layers of soil. Each one of those helical plates spreads the building's weight out over a wider area. This gives it a really incredible grip compared to a simple straight-sided pile.

The installation itself is pretty clever. Our equipment constantly measures the torque—basically, how hard it is to keep twisting the pile. That reading tells our engineers exactly when the pile has hit solid, stable ground and can hold the required load. We get real-time confirmation that it’s going to perform, which gives us and our clients a ton of confidence.

And they’re incredibly versatile. Whether we're dealing with soft clay near the surface or loose sand, we just keep driving the pile down until it hits a layer of soil that can do the job. The steel itself is built to last, holding up against whatever the ground throws at it.

From Lighthouses to Smart Homes: A Brief Evolution

It's pretty amazing to think about where these started. We’re talking way back in the 1830s, when engineers were trying to figure out how to build lighthouses on sandy, unstable coastlines. They needed something that wouldn't sink or shift, and the screw pile was born. To be fair, they were installing them by hand back then, which is hard for our crews to even imagine.

The idea caught on through the mid-1800s for things like piers and bridges along the water. But it was still a manual process, which really limited how big the projects could get.

For us as engineers, the real game-changer was modern hydraulics in the 1950s. Suddenly, machines could do the work, driving piles deeper and with more power than ever before. That’s when the technology broke out of its coastal niche and people started seeing its potential everywhere.

The 1980s marked significant growth in residential use. Contractors discovered helical piles worked well for:

- Foundation repairs

- Underpinning existing structures

- New home construction on poor soils

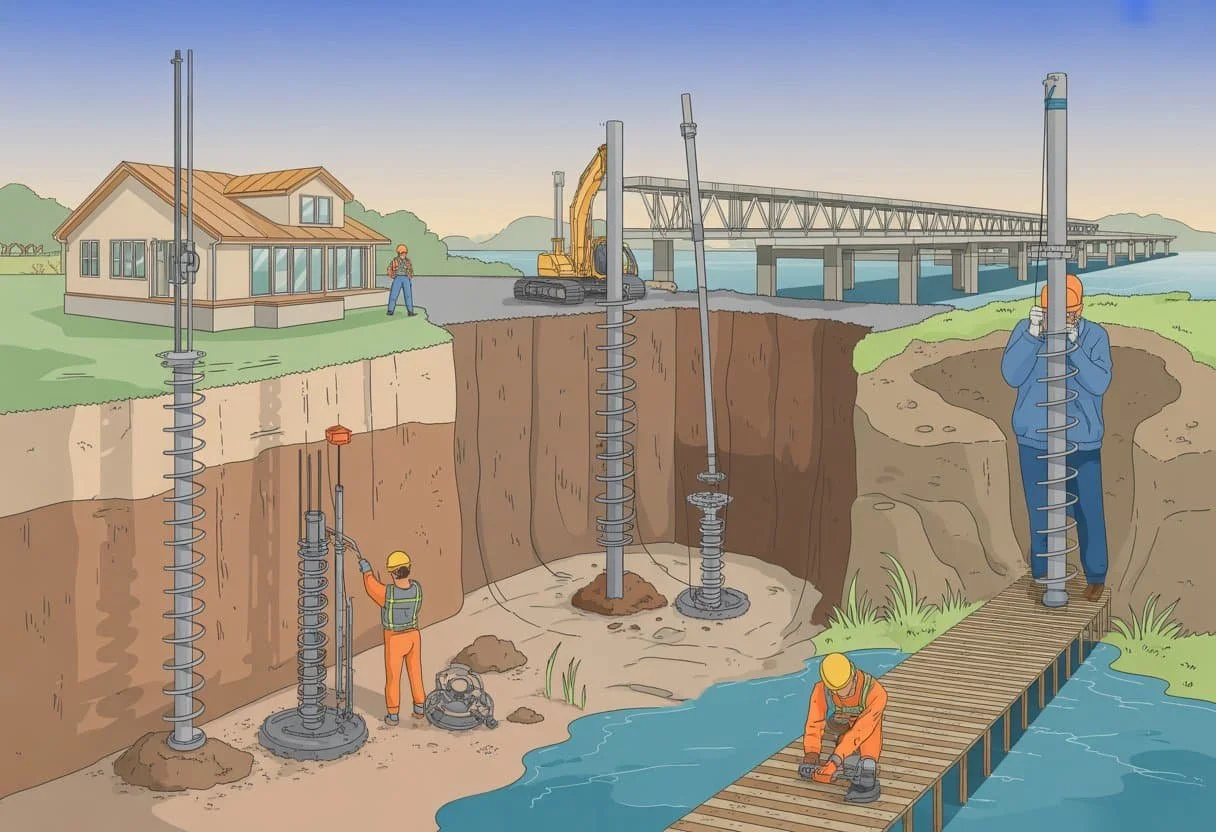

Now, we see them everywhere. For homes, they're used for everything from deck footings to entire foundations. In the commercial world, they’re holding up retail stores, warehouses, and offices.

Infrastructure projects rely on helical piles for:

- Transmission towers

- Highway signs

- Bridge foundations

- Solar panel arrays

Even smart home tech is creating new uses. You need a solid base for solar panels or EV charging stations, and helical piles provide that without a big fuss.

The equipment just keeps getting better. The level of control and real-time data we have now is incredible. It’s been a long journey from those first hand-cranked lighthouse foundations, but that evolution shows just how adaptable and reliable the core idea has always been.

How Installation Works - Step by Step

Let's walk through what this actually looks like on a job site. First off, there’s barely any digging compared to a concrete job. We just need to clear the area and make sure our machine can get where it needs to go. Even our smaller equipment can get into really tight backyards, which is a huge plus for many projects.

A piece of equipment called a hydraulic drive head gets attached to the top of the pile. This is what does all the work, rotating the pile into the ground like a drill bit. As it turns, those helical plates just pull it downwards, slicing through the soil.

Torque monitoring happens throughout the entire process:

- Drive head measures rotational resistance

- Engineers track readings in real-time

- Values indicate soil bearing capacity

- Installation stops when target torque is reached

If we need to go deeper, we just bolt on another section and keep going. It’s a seamless process until the pile hits that sweet spot of stable soil and the torque readings tell us it’s locked in.

Load application occurs immediately after installation:

- No curing time required

- Structural brackets attach directly to pile heads

- Building loads transfer instantly

- Construction continues without delays

The whole process is incredibly clean. There’s no excavated dirt piled up, no concrete trucks coming and going. Once the piles are in, our equipment leaves, and the site is ready for the next phase.

And the weather almost doesn’t matter. Rain, cold—it doesn’t stop the work, which is a massive relief for keeping a project on schedule.

Honestly, for a typical house, we can have the foundation done in a matter of hours. Not days. For commercial jobs, we’re saving our clients weeks compared to the old way. And we’re left with almost no waste to clean up.

Built for Versatility: Where Helical Piles Are Used

We use these across almost every sector of construction. Their design makes them a go-to solution for small jobs in a backyard and for massive commercial structures.

Residential Applications

This is where a lot of homeowners first encounter them. They're perfect for deck foundations, additions, or sunrooms, especially when you don't want to tear up an established garden to get a concrete truck in.

And they are lifesavers for foundation underpinning. When a house starts to settle, we can use helical piles to stabilize it without having to excavate the entire foundation.

Commercial and Industrial Projects

Those tall cell phone towers need incredibly stable foundations that go deep, and helical piles are often the answer.

You'll also see them used for bridge abutments and the foundations for piers. And the solar industry loves them—we can install the support racks for thousands of panels quickly and with minimal impact on the land.

Challenging Construction Sites

| Site Type | Why Helical Piles Work |

|---|---|

| Tight urban lots | No large equipment needed |

| Wetlands | Minimal ground disturbance |

| Sloped terrain | Adapts to uneven surfaces |

| Frost zones | Installed below frost line |

This is where they really shine for our clients—on those nightmare sites. Got a tiny urban lot where a concrete truck can't even dream of fitting? Helical piles are your answer.

Working in or near wetlands where you have to be careful about environmental impact? The low-disturbance nature of the installation is perfect.

Building on a steep slope has always been a headache. But we can install helical piles at different angles and elevations to create a level foundation.

And in cold climates, you have to get your foundation below the frost line so it doesn't heave. We can easily drive helical piles deep enough to get past that problem for good.

Performance That Stands Out

From our perspective, the advantages are clear and measurable; they aren't just a convenient alternative. It comes down to speed, minimal impact, and proven, adaptable strength.

Speed And Efficiency

This is the part that consistently impresses our clients. A residential foundation can be done in a few hours. We're talking about saving weeks on a commercial project timeline.

- Helical piles install in minutes rather than days. A typical residential foundation takes 4-6 hours to complete. Commercial projects finish weeks ahead of concrete alternatives.

- The installation process eliminates cure time completely. Structures can bear loads immediately after installation. This reduces project timelines by 30-50% compared to poured concrete foundations.

- Equipment mobilization requires minimal space. A single truck-mounted installer handles most residential projects. The compact footprint allows work in tight spaces where concrete trucks cannot access.

- Weather delays become rare occurrences. Installation continues through light rain and freezing temperatures. Concrete foundations require specific temperature ranges and dry conditions.

- Load testing happens during installation. Torque monitoring provides real-time verification of bearing capacity. This eliminates guesswork and ensures proper performance from day one.

Quiet And Low Impact

On any project in a built-up area, this is a huge deal for us and our clients. It’s about being a good neighbor and not shaking the house next door to pieces.

- Installation noise stays below 85 decibels at 50 feet. This matches typical traffic levels. Concrete pumping and mixing equipment generates significantly more noise.

- Vibration remains minimal during the helical installation process. Neighbouring structures experience no settlement or damage. Pile driving creates ground vibrations that travel hundreds of feet.

- Site preparation requires no excavation. The installer advances piles directly through existing soil. Traditional foundations need extensive digging and soil removal.

- Material delivery uses standard trucks. A typical project needs one delivery trip. Concrete foundations require multiple concrete truck visits plus rebar and form deliveries.

- Soil displacement stays under 3% of pile volume. The helical plates compress soil rather than removing it. This preserves site drainage and reduces waste disposal needs.

Strong And Scalable

Don't let the simple installation fool you; these things are incredibly strong and can be engineered for almost any load. It’s all about getting deep enough to find good soil.

- Load-bearing capacity reaches 200 tons per pile for large commercial applications. Residential piles typically handle 15-40 tons each. The helical design transfers loads efficiently to stable soil layers.

- Pile lengths adjust to site-conditions. Standard installations range from 10-80 feet deep. Custom applications extend beyond 120 feet when required.

Multiple pile configurations accommodate different load requirements:

- Single helix for light loads

- Double helix for standard residential

- Triple helix for heavy commercial structures

- Lateral resistance exceeds traditional concrete piles. The helical plates provide superior resistance to wind and seismic forces. This makes them ideal for tall structures and unstable soils.

- Quality control happens during installation. Torque measurements correlate directly to bearing capacity. This provides immediate verification without waiting for concrete strength tests.

Sustainable By Design

This is becoming more and more important to our clients, and for good reason. The environmental case for helical piles is really strong.

- Steel piles contain 90% recycled content. The manufacturing process uses existing steel stock. This reduces environmental impact compared to concrete production.

- Installation generates zero concrete waste. No forms, excess concrete, or contaminated soil requires disposal. Traditional foundations create 2-4 cubic yards of waste per project.

- Removal and reuse becomes possible when structures reach end of life. The helical design allows extraction without damage. Concrete foundations become permanent waste in landfills.

- Carbon footprint drops 40% compared to concrete alternatives. No cement production or concrete truck emissions occur. The manufacturing process uses standard steel production methods.

- Site restoration happens immediately after installation. No curing areas or material storage remains on site. Landscaping and final grading begin the same day.

Where They Might Not Fit

Look, we believe in using the right tool for the job, and helical piles aren't a silver bullet for every single site. If we try to screw one into shallow bedrock, we’re not going to get very far. The plates just can't penetrate solid rock.

The same goes for ground that’s filled with huge, unpredictable boulders. Hitting one of those can stop the installation cold or even damage the pile itself.

A really high water table can also make things tricky. It’s not that it can’t be done, but it might require different equipment or techniques, and that can drive up the project cost.

And for some very specific engineering needs, like a structure that has to resist immense sideways forces without any other bracing, we might need to look at other deep foundation options.

| Challenging Conditions | Primary Concern |

|---|---|

| Shallow bedrock | Cannot penetrate rock |

| Large boulders | Equipment obstruction |

| High water tables | Installation complications |

| Extreme lateral loads | Capacity limitations |

Sometimes really hard, dense soil can be a problem too. The amount of torque needed to get the pile in might be more than our equipment can handle.

And there's a practical limit to how much weight a single pile can support. For exceptionally heavy buildings, we might need a different approach.

This is why a good geotechnical report is non-negotiable for our team. We have to know what we’re dealing with under the surface before we commit to a foundation type. But even with these challenges, our engineers can often find a way to make it work.

Design Considerations That Make Or Break A Project

This is where our engineering team really gets to work. You can't just grab a pile and stick it in the ground. The design behind a successful helical pile foundation is critical, and it all starts with understanding the soil. We need to know what we’re dealing with every foot of the way down.

The size of the steel shaft itself—its diameter and how thick the walls are—is directly tied to how much weight it can carry. A beefier pile can handle more load, but it's also a bigger investment.

The soil type dictates everything about the helix plates. Sandy soil behaves differently than clay, so we need the right size and number of plates, spaced correctly, to get the grip required.

Engineers calculate the number and size of helix plates based on:

- Expected vertical loads

- Lateral force requirements

- Soil conditions at installation depth

- Required safety factors

Corrosion is another big one. If we're building near the coast with salty air, or in soil with certain chemicals, we need to protect the steel with a galvanized coating. You can't just ignore that.

How deep we need to go is determined by things like the local frost line and where the strong, stable soil layers are. We have to get deep enough to be sure.

The torque reading during installation is our real-time check. It confirms that the soil we're hitting in the field matches what our engineers predicted in the office.

We also have to be careful about how close we place the piles to each other. Put them too close, and they can actually start competing for the same soil, which reduces how much they can hold.

Even something as simple as site access plays a role. If we can't get a big machine in, we might have to use shorter pile sections and bolt more of them together on-site. It’s all part of the planning.

Tools Of The Trade: Installation Equipment And Monitoring

For any installation, we need the right tools. For tight spots, like a backyard project, a skid steer with a drive head attachment works perfectly. For bigger jobs with deeper piles or tougher soil, we bring in an excavator to provide the necessary power and stability.

The key is that the equipment has to generate enough torque to get the piles to the target depth. And just as important is the system that monitors that torque. It's the feedback that tells our operator when the job is done right.

Our modern rigs have digital screens that give the operator a constant readout of the torque. Some of them even log all the data, so we have a complete record of every single pile that goes into the ground.

Installation equipment typically includes:

- Hydraulic drive motors

- Torque measurement systems

- Depth tracking devices

- Data recording equipment

It's crucial that this monitoring gear is calibrated correctly on our rigs. Accurate readings are everything; they’re what guarantee the foundation will perform as designed.

Having that detailed record of each installation is a huge asset. It proves that every pile met the engineering specs, which is great for inspections and final project documentation.

At the end of the day, that torque reading is our primary measure of success. It tells us when we've hit our target, ensuring the pile is perfectly installed—not too deep, not too shallow.

Real Projects, Real Results

Theory is great, but let's talk about what this looks like in the real world. We've had some challenging projects where these really saved the day. We had this one residential retrofit in Toronto that was a real headache. A century-old house on terrible clay soil, with basically no access for equipment. A concrete foundation was out of the question.

Project Details:

- Location: Downtown Toronto

- Challenge: Poor soil conditions, narrow lot access

- Solution: 18 helical piles installed by hand-held equipment

- Timeline: 3 days vs. 2 weeks for concrete alternative

The piles went in, and the load was transferred immediately. No waiting.

Then there was a solar farm out near Calgary. They needed to put foundations across a huge 50-acre piece of farmland, and the client was adamant about not tearing up the fields.

Key Results:

- 400 helical piles installed in 10 days

- 90% less soil disturbance than concrete footings

- Farming resumed immediately after installation

- No heavy machinery damage to crop areas

And one that really sticks with us was an emergency job in Winnipeg. A warehouse foundation was damaged by spring flooding, and the whole building was starting to settle. They needed a fix, fast.

Emergency Response:

- Site assessment within 24 hours

- 32 helical piles installed in 5 days

- Building operations resumed immediately

- $200,000 saved compared to full foundation replacement

In each of these cases, it was the adaptability of helical piles that made the difference. The speed and the immediate strength kept these projects from turning into costly failures.

A Smarter Alternative To Traditional Footings

This is usually the point where it all clicks for our clients. When you put helical piles head-to-head with traditional concrete footings, the advantages become really clear. For us, it comes down to less time, less mess, and fewer headaches.

The speed is just no contest. With concrete, you’re digging, forming, pouring, and then waiting. With helical piles, we’re installing and ready to build on the same day.

Weather is another big one. How many projects have been delayed waiting for the right conditions to pour concrete? Helical piles go in year-round.

And the immediate load capacity is a game-changer. You don't have that 28-day waiting period for concrete to cure. The moment the pile is installed, it’s ready to do its job.

| Feature | Traditional Footings | Helical Piles |

|---|---|---|

| Installation time | 3–7 days | 2–6 hours |

| Weather restrictions | Yes | No |

| Load capacity | 28 days | Immediate |

| Excavation required | Extensive | Minimal |

Cost Benefits

- Lower labour costs due to faster installation

- Reduced equipment rental time

- No concrete material costs

- Minimal site disruption

Inspection and Documentation

The real-time torque monitoring gives us on-the-spot confirmation of the foundation's capacity. You just can't get that with concrete.

Future Flexibility

f plans change down the road, helical piles can actually be removed. A concrete footing is a permanent obstacle.

Project Suitability

They’re just as effective for a small home addition as they are for a large commercial building. And for renovations, the ability to work without major excavation is priceless.

The technology really proves its worth on those difficult sites where a traditional footing would mean bringing in tons of engineered fill or excavating way deeper than is practical.

Is A Helical Pile Right For Your Build?

So, how do we help you figure out if a helical pile is the right call for your project? The first thing we look at is your soil. If you're dealing with clay, sand, or other mixed soils, you're likely in good shape. If your site is mostly shallow rock, we’ll probably need a different solution.

You absolutely need a geotechnical report report before you decide anything. It’s the only way for us to know for sure what’s going on underground.

We also look at access. If you have a tight site with limited room for big machines, helical piles are a very attractive option.

What's your timeline? If you can't afford to lose weeks waiting for concrete to cure, helical piles are often the obvious choice.

And we always consider the surroundings. If you’re in a dense area, the minimal noise and vibration of a helical installation can save you a lot of complaints.

| Factor | Helical Piles | Concrete Piles |

|---|---|---|

| Installation speed | Same day | 7–28 days |

| Vibration level | Minimal | High |

| Access requirements | Small equipment | Large equipment |

Our best advice is always this: talk to a structural engineer early in the process. We can assess your specific site conditions, load requirements, and help you make an informed decision.

And make sure you use a certified installer. This isn't a DIY job. The performance of your entire structure depends on their expertise. Contacting a specialist during your planning phase is the smartest move you can make.

Summary And Next Steps

At the end of the day, it’s not just about the steel or the torque readings. For us, it's about finding a better way to build. We’ve seen that look of relief on a homeowner’s face when they realize their settling house can be fixed without destroying the yard they love. We’ve felt the energy shift on a commercial project when the schedule gets pulled forward by weeks because we didn’t have to wait on concrete. That’s what this is really about for us at Exactus.

This technology represents a shift in thinking—toward solutions that are more efficient, less disruptive, and more in tune with the realities of modern construction. Our job is to bring that technical expertise to your project, to look at your specific challenges and design a system that just works. It’s a responsibility we take seriously, because we know that a solid foundation is where every successful project begins, and we're the ones who have to stand behind it.

Why choose helical piles?

- Speed: Installation happens in hours, not days

- Versatility: Works in challenging soil conditions

- Sustainability: Minimal excavation and site disturbance

- Reliability: Immediate load-bearing capacity

Exactus Engineering brings advanced technical capabilities to every helical pile project. Our structural engineers analyse soil conditions, calculate load requirements, and design systems that meet specific project needs.

We use specialized equipment and proven installation techniques. Quality control measures ensure each pile meets design specifications before construction proceeds.

Ready to explore helical pile solutions for your project?

Our team can assess your site conditions and provide detailed engineering recommendations. We offer comprehensive services from initial design through construction support.

Take the next step:

- Get a site review from our engineering team

- Download our design guide for technical specifications

- Schedule a consultation to discuss your project requirements

Contact Exactus Engineering today to discover how helical piles can provide the stable, efficient foundation solution your project demands.